Turbines don’t spin forever, and with the operational lifetime of an offshore wind farm averaging around 20-25 years, much of the UK’s existing wind power infrastructure is aging quickly.

With dated infrastructure, many developments are facing decommission.

But what does that mean for existing assets, and how can repowering efforts help push back eventual full decommission to keep projects viable for longer?

One platform tackling every project stage…

NeuWave’s tools span from site assessment through navigation and logistics, offering integrated insights to reduce downtime and boost ROI across your asset’s lifespan.

Let’s take a look.

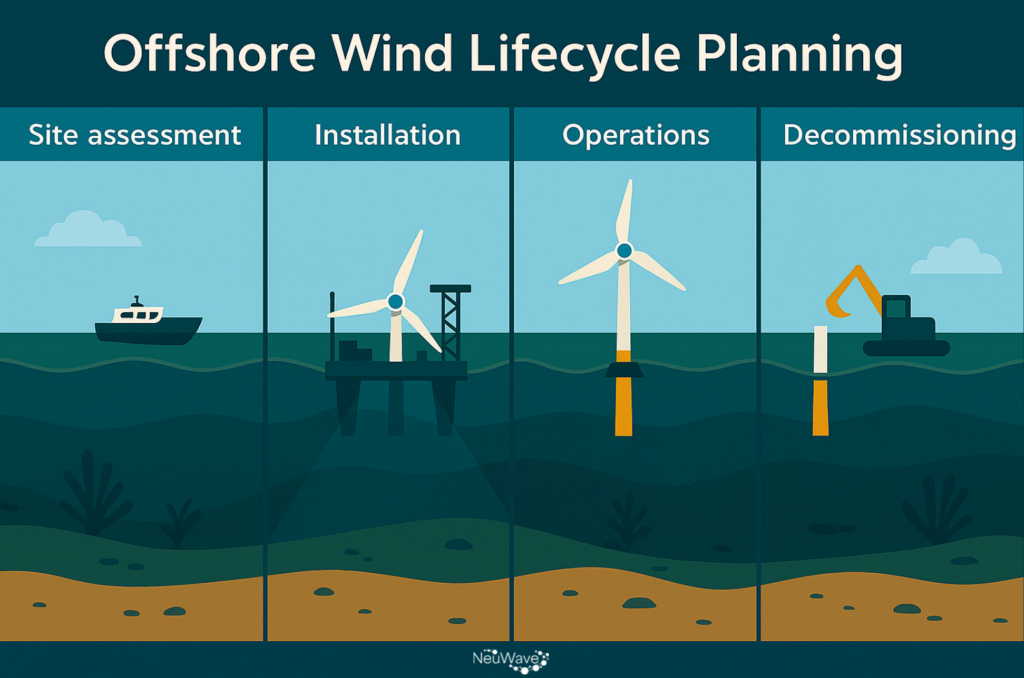

Wind turbine lifecycle stages

We’ve been over the offshore wind turbine lifecycle before, but as a quick refresher…

Nothing is simple when it comes to offshore wind farm logistics. Right from the start, site assessments and project development is usually a multi-year, multi-million pound endeavour.

Developers evaluate potential wind resources, metocean conditions, seabed geology, grid connectivity, and environmental sensitivity, culminating in feasibility studies, EIAs, and stakeholder and community engagement, all before construction even begins.

Once planning consents are secured and equipment is fabricated, the project transitions into installation and commissioning. Foundations are laid and blades, towers, and nacelles assembled – port-side prep followed by offshore lifts.

This phase is intensely weather-dependent, with operations driven by precise forecasts to maximise safe windows, vessel usage, and cost efficiency. Commissioning completes the phase, with each turbine tested and connected to the grid.

Operations, maintenance, and servicing account for 20–25 % of a wind farm’s lifetime cost; and continue throughout a wind farm’s lifetime. This entails routine inspections, component replacements, remote monitoring, and yet more weather-constrained logistics.

The journey of a wind turbine stretches well beyond its final bolt.

How are wind turbines decommissioned?

Decommissioning of the earliest generation of wind turbines is already underway; and it’s proving to be a costly process that takes considerable time and resources. It’s not as simple as just knocking them down, especially when removing those we’ve placed offshore.

Offshore Energy UK (OEUK) released detailed guidelines in November 2024, intended to guide project teams through deconstruction, depowering, logistics, and recycling of decommissioning offshore wind farms.

The main steps of offshore wind turbine decommission are:

- Decommissioning assessment: What are the projected impacts, costs, and requirements?

- Preparation: Vessel and port bookings, environmental and weather conditions checks, etc.

- Removal of infrastructure: Including turbines, substructures and foundations, and electrical equipment

- Transportation to port: Route planning, team safety, logistics at port

- Waste management: Reuse/recycle/dispose of materials appropriately

Currently, the majority of turbines nearing their end of life are smaller turbines, located closer to the shore. This is manageable for now, but as larger installations further out to sea reach their decommissions, we’ll have all new challenges – more hostile, volatile environments; and vessels that potentially aren’t big enough for the job.

Vessel expenses make up between 60-80% of decommissioning costs…

With upcoming NeuWave navigation tools, cut unnecessary down time and trim the fat on wasted resources.

Can wind turbines be recycled?

It’s a common misconception that wind turbines cannot be recycled – with around 95% of a turbine being made from widely recycled materials, including steel, copper, aluminium, precious metals and recyclable plastics.

However, most turbine blades are made from fiberglass; it’s resilient and flexible. But fiberglass isn’t biodegradable, and the plastic and glass strands that make up its “fibers” can be difficult to process for recycling.

Scientists are still researching ways to repurpose and recycle fiberglass wind turbine blades, and there’s still no standard legislation to guide the best practices. It leaves the industry on shaky ground when it comes to wind turbine decommission and how to process the potential waste.

What is wind turbine repowering?

Rather than being fully replaced when decommissioned, repowered wind turbines are those that have been retrofitted with next-generation assets that keep it functionable. Full repowering doesn’t happen often, it’s a big undertaking.

But, “it’s happening and will increase,” said WindEurope CEO Giles Dickson. To date there have been around 125 successful wind farm repowers. And as ever-more older turbines reach their lifecycle end, repowering may become a necessity.

Full repowering of a wind turbine typically involves replacing the turbines, rotors and electrics, and foundation – and this is even more complicated at sea.

It’s not always as simple as repowering the existing architecture; redesigns are also subject to permit reviews and relevant regulatory frameworks. If the planned updated turbine can’t meet the required standards, it will likely just be decommissioned.

Repowering vs decommission – which is best?

At the end of the day, once an offshore wind project has been decommissioned it can no longer produce energy for the grid, or future revenue for its owners. If the site is cleared for repowering, this is always the optimal solution.

But full wind turbine repowering in 2025 remains an expensive solution, and it’s still more common for developers to choose to partially repower assets. This can double the lifespan of the turbine, and costs significantly less.

Whether it’s due to outdated infrastructure viability, or changing climate and weather conditions, it’s not always a question of which is the best choice. Eventually, all existing wind power assets may need to be decommissioned.

The key to success is in robust planning. Designing today’s projects with their end-of-life in mind, so future transitions, whether through repowering or removal, are safer, faster, and more cost-efficient.

Precise sea-state imagery at 500m resolution enables smarter decisions…

Leverage NeuWave’s high-resolution environmental insights to optimise site assessment, minimise uncertainty, and streamline foundation planning.